Trolley tumbler

- Category

- Stainless steel equipment

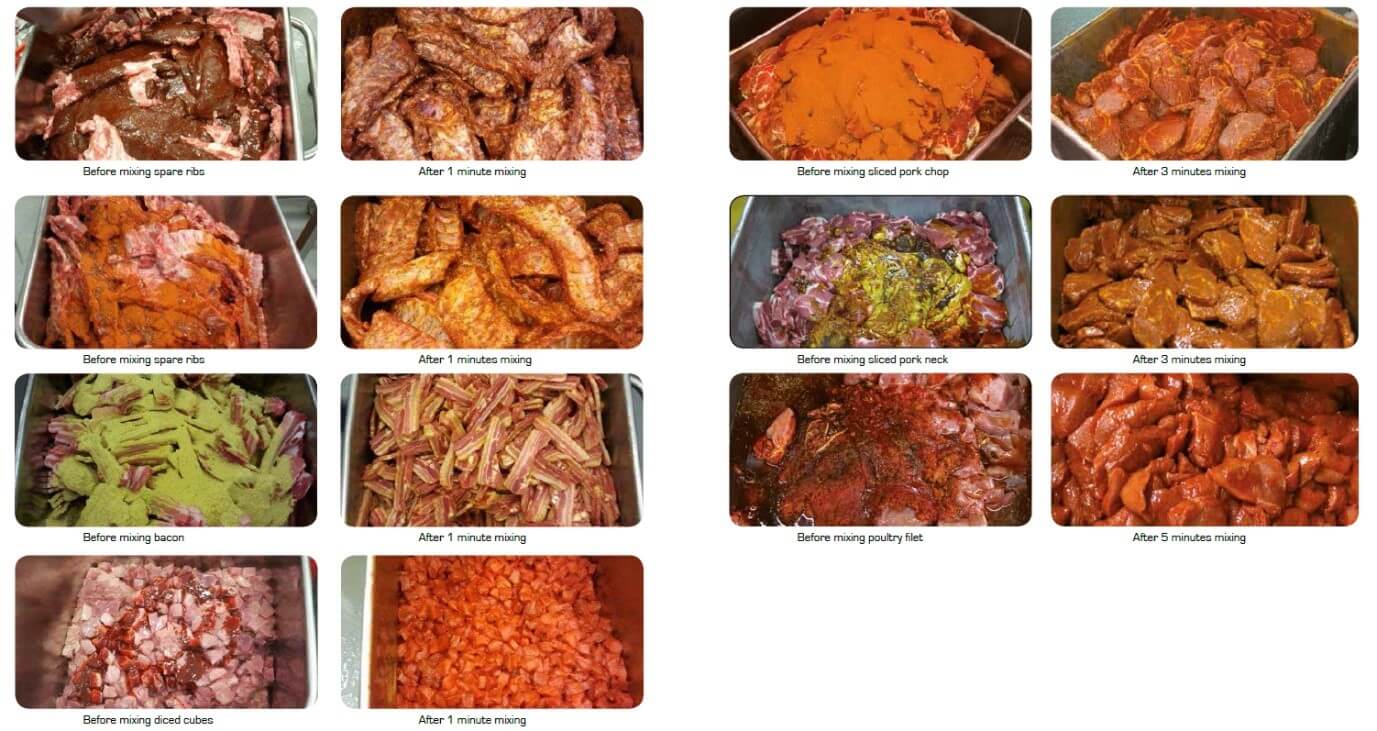

The complete answer to the tumbling and/or mixing need for whole meat products such as poultry, ham stop- and silversides, pork loins, minced products of meat, fish, vegetables, salads etc. The range and versatility is nearly unlimited.

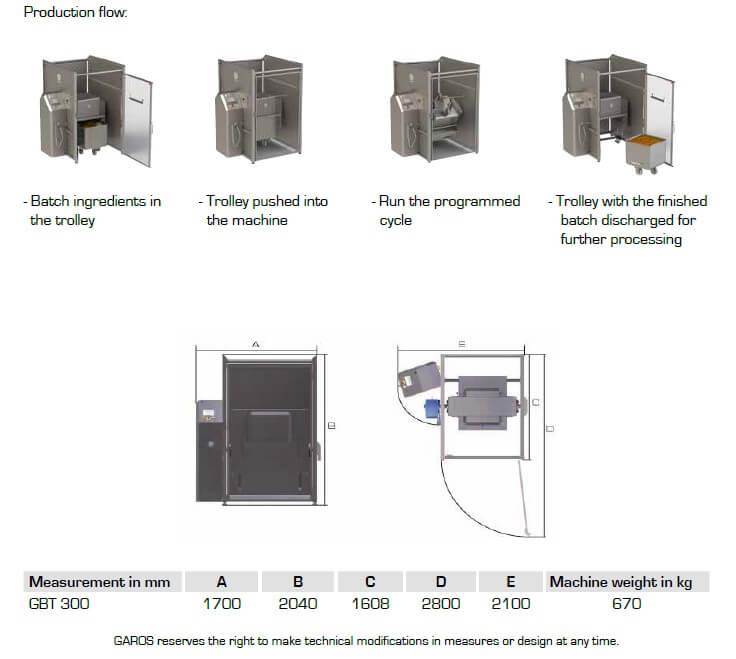

GBT 300 works with standard 200 liter trolleys and manages 200 kg of product each work cycle. It can reach a vacuum grade up to 50 percent. (For higher grade of vacuum reinforced trolleys can be used.) Note that the hood above the trolley has the same volume 200 liter, as the trolley containing the products. This ensures a thorough tumbling/mixing/marinating of the content. This also means that the trolley can be loaded to its maximum, 200 kg per work cycle is stated we refer to red meat. Product with less specific weights may need more space.

On the digital display you can easily program start time, vacuum on and off and interval running. When time is out, the tumbler with trolley stops in exact position. One press on the button for “down” and the trolley goes down and can be pulled out. GBT 300 is ready to be reloaded. GBT 300 is very easy to hold in a high hygienic standard and has very moderate requirements on maintenance. Hints: Tumbling hams 600 – 800 kg per day Spicing chicken parts then only a couple minutes is needed, which gives a capacity of 2000 kg per hour.